Services

-

01 QUOTATION

-

02 PROCUREMENT

-

02 MANUFACTURE

-

04 INSPECTION

-

05 DELIVERY

Precision Grinding

We offer precision grinding services, enabled through our onsite specialist machinery & skills. We are able to grind a vast array of materials.

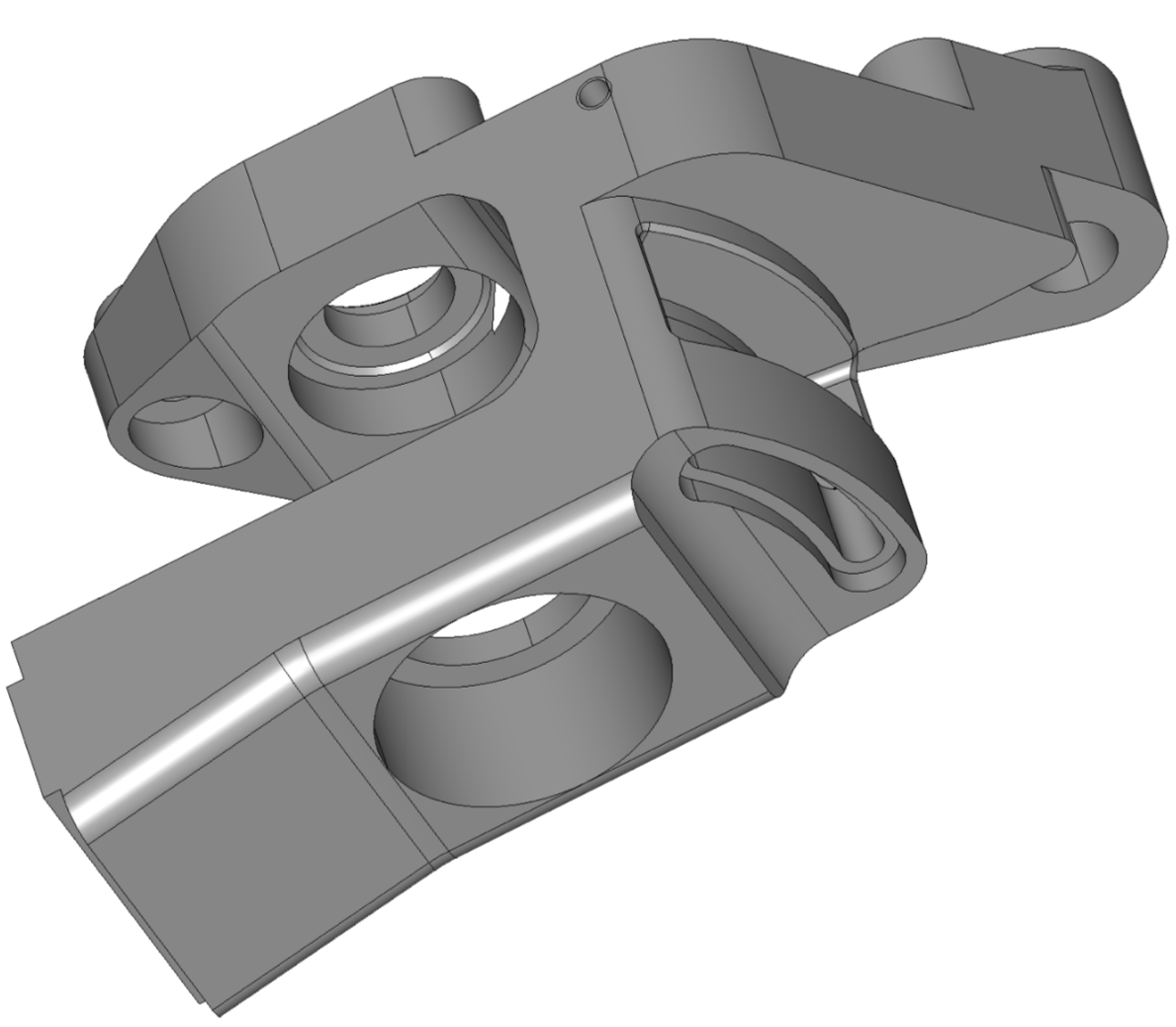

Cad Cam Facilities

We have the latest CAD / CAM software which can accept various file formats of 2D and 3D Data. We are able to manufacture and inspect using the following software suites -One CNC (Up to 5 Axis)

Feature Cam Ezcam

Spaceclaim

Ablink Inspect to Cad.

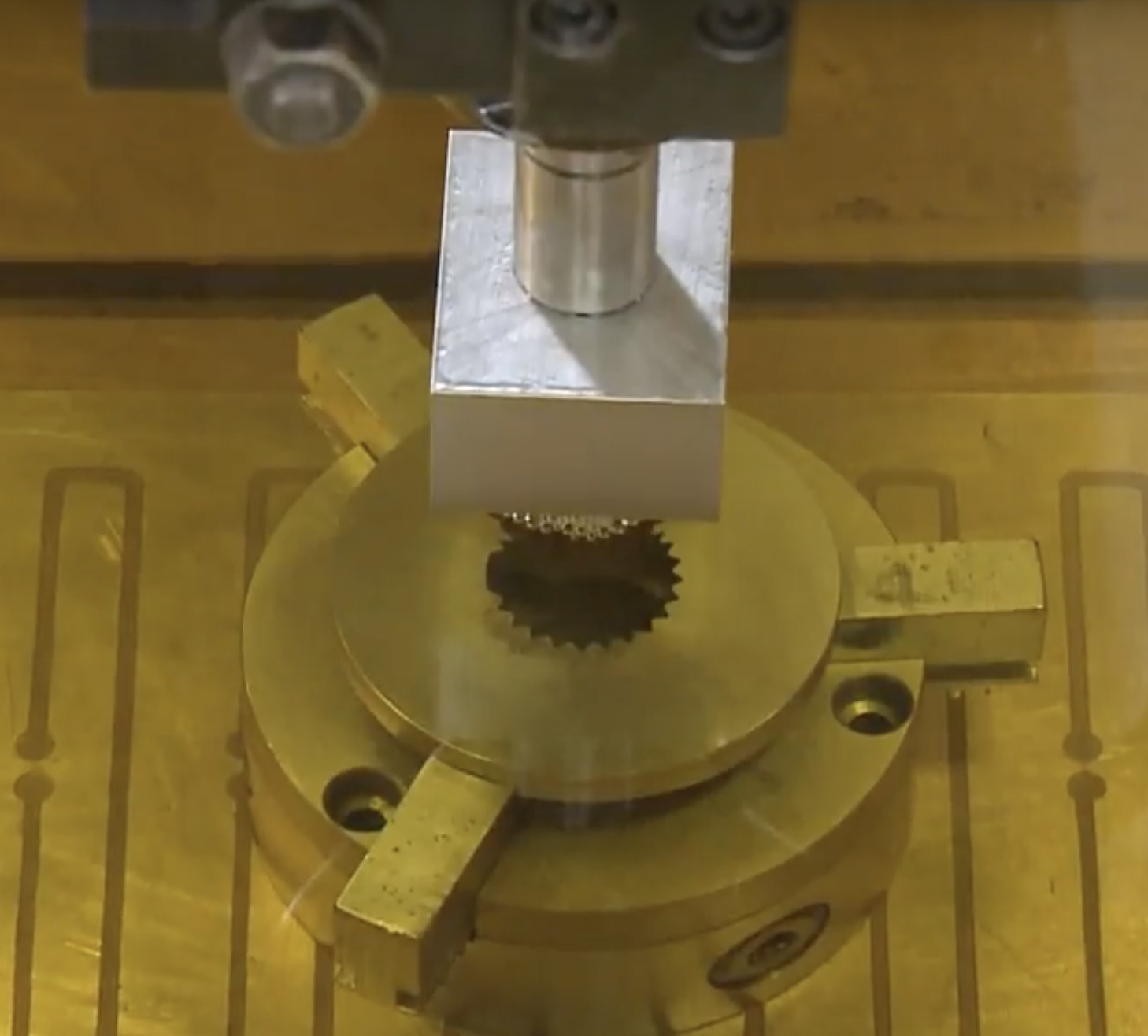

Spark Erosion

Using our Spark Erosion EDM facilities; we are able to manufacture complex shapes in a wide variety of conductive materials.

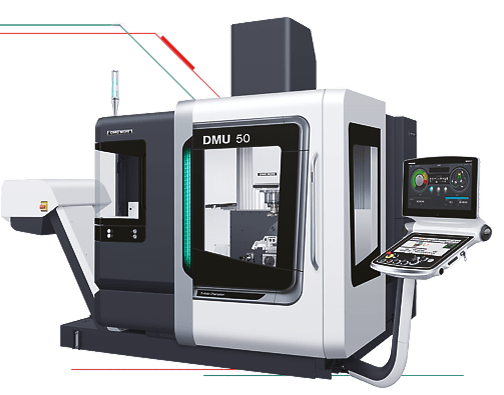

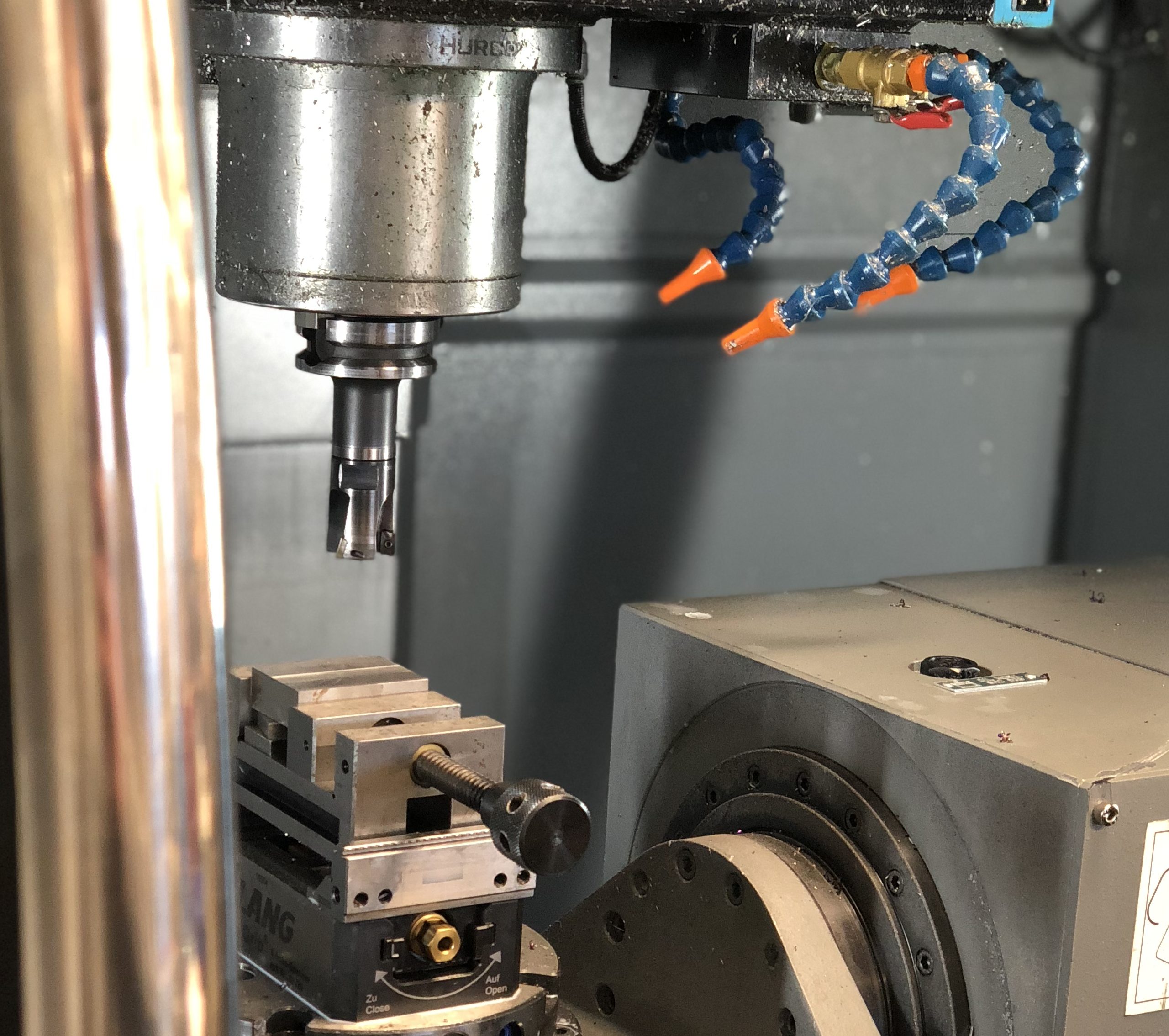

CNC Milling & Turning

Through our continued investment in machinery; we are able to provide both CNC milling & turning. With a wealth of experience working with many specific materials with high tolerance requirements.

Wire Erosion

Our extensive wire erosion (wire EDM) capability enables us to machine parts which have extremely tight tolerances and complex shapes.

Heat Treatment

In partnership with our approved contractors, we are able to offer a complete manufacturing solution, including heat treatments and surface coatings.

5 Axis Machining

Our latest 5 Axis machining technology, enables us to offer an even faster turn around on precision components, from difficult materials and to complex shapes.

Laser Marking

Our advanced laser marking facility provides ability to mark complete components with customer specified requirements; enabling greater part tracking.

Quality

Our facilities are ISO 9001:2008 and ISO 14001:2004 accredited. Strengthening our undertaking of quality throughout our process. We are able to offer full traceability of our customer components using our “Redant” production control software and first article reporting with Visual FAIR.

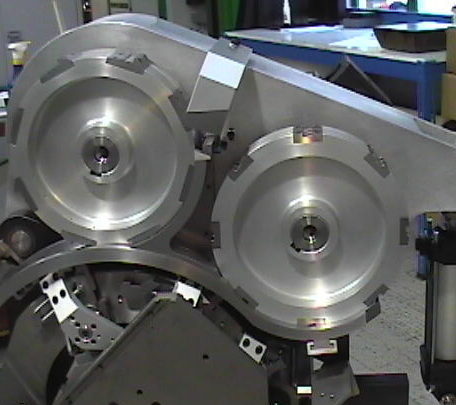

Special Purpose Machinery

We manufacture and build special purpose machinery to customers design and specification. We work in partnership with our customers and undertake development and process control of bespoke equipment.

Toolmaking & Pressing

CSL Engineers Ltd offer a full Toolmaking and pressing service of low volume high quality components We manufacture press tools and pressed components to customer design and specification.

Delivery

We provide a same day service using our own vehicles for local deliveries of precision components, assemblies and tooling. We are also able to offer a next day service using TNT.For overseas customers we are able to offer delivery via DHL, usually next day within Europe.